Environment/Recycling

Environment

All our products contribute to the improvement of the environment through their characteristics. For example, as insulation material there is far more energy saved in use than is consumed to manufacture and install our products. For a short introduction to the many uses of EPS and its recycling possibilities please click this link to the EPS Explained video.

Sustainable Energy Supply

To reduce the environmental impact of our manufacturing processes we use 100% renewable electricity backed by REGO Certificates at all our UK factories. We are committed to reducing our carbon emissions wherever possible and support the UK strategy of achieving the goal of net zero carbon by 2050.

EPD

The excellent environmental performance of EPS is demonstrated in the Environmental Product Declarations (EPD). Generic EPD’s have been produced for the main types of EPS by our partner Association – EUMEPS (European Manufacturers of EPS).

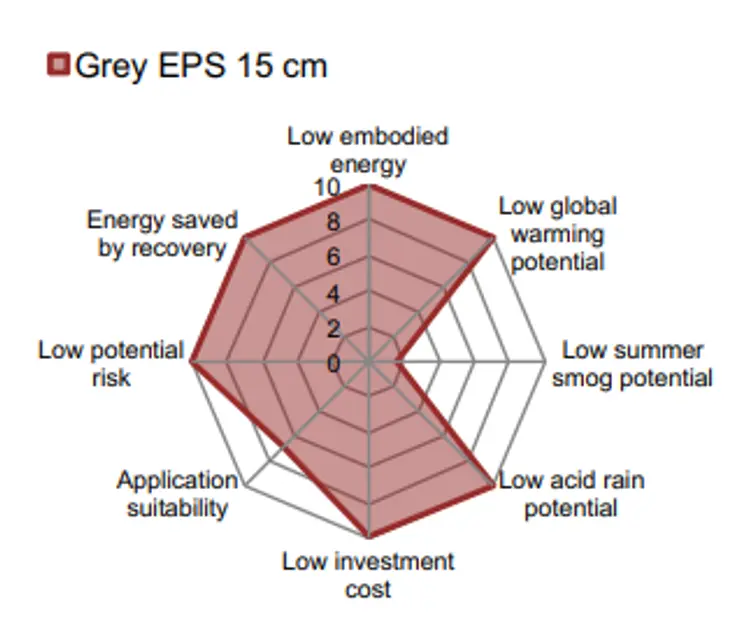

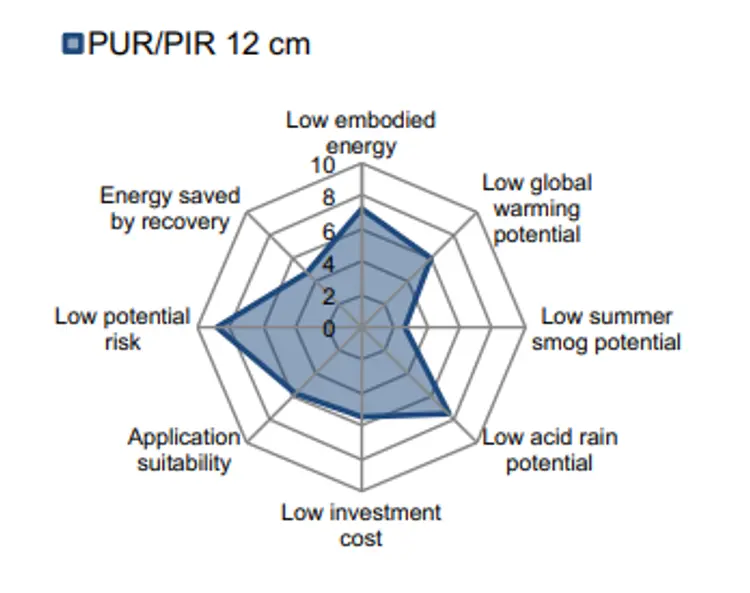

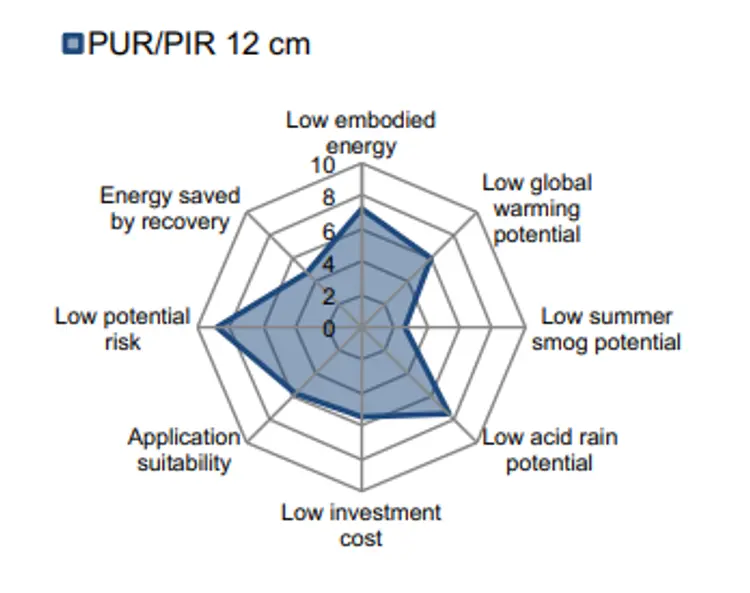

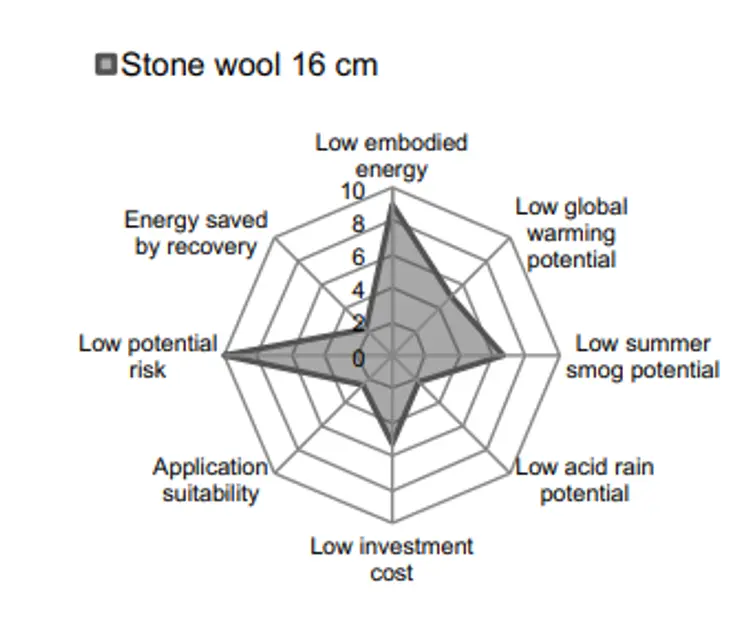

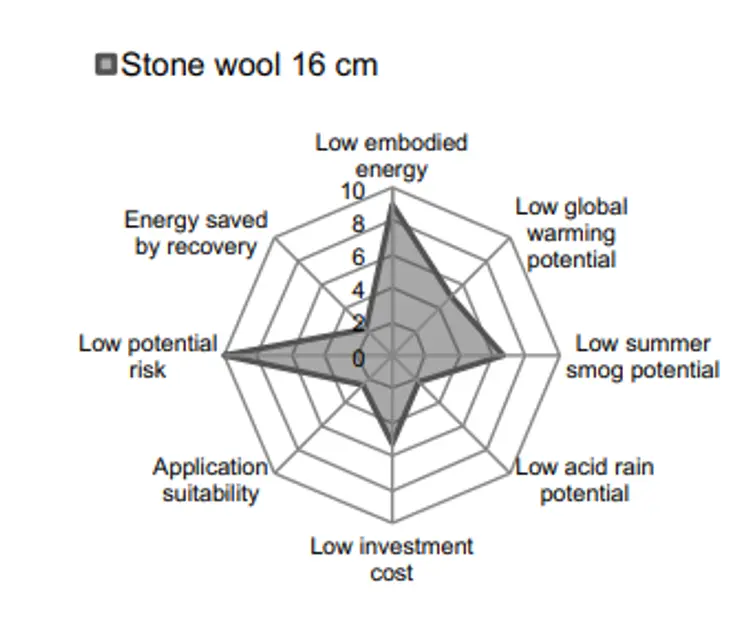

The spider diagrams below are an extract from a recent multi-criteria comparison of insulation materials carried out for EUMEPS. These are taken from the External Wall Insulation comparison and shows EPS having the lowest overall environmental impact.

Note! When comparing product EPD’s a true picture will only be achieved if the comparison is made between equally beneficial products i.e. not only in thermal performance but also in compressive strength and other significant properties.

BREEAM

EPS achieves A+, the best possible environmental impact rating in the BRE Green Guide to Specification. This ensures maximum points are scored in the BREEAM assessment of the project with EPS having low environmental impact.

All our construction products are manufactured in the UK under an Environmental Management System to ISO 14001. All raw materials used in our process are responsibly sourced from manufacturers also operating an EMS and Certified to ISO 14001.

Expanded Polystyrene – EPS – Sundolitt

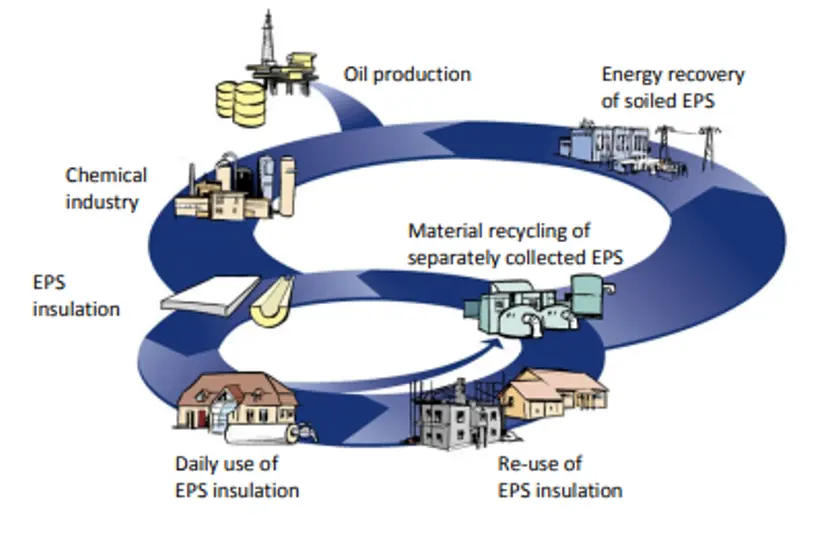

EPS is a by-product of the refining of crude oil which is considered a non-renewable resource. Over 83% of the derivatives from crude oil are directly transformed into energy in one form or another, transportation fuel, electricity generation, heating. Only 4% is used for making plastics and less than 0.1% is used to produce EPS.

Creating EPS insulation products for construction is an efficient use of this natural resource. Every 1kg of oil used to make EPS insulation will save the environment from burning 150kg of oil for heating the building over its service life of 50 years.

Effective and efficient thermal insulation therefore saves a considerable amount of fossil fuel (non-renewable resource). A reduction in the emissions that contribute to the so-called Greenhouse Effect is also achieved by saving energy used for heating.

Materials

Pentane

In the production of EPS, the natural gas Pentane is used as an expansion agent. Pentane is not a CFC or HCFC and is not an ozone depleting chemical. It is also known to be produced from anaerobic decomposition of plant material. Two-thirds of the pentane content of the raw material is released during and shortly after manufacture. The released pentane is degraded by sunlight (photochemical) to CO2 and water vapour.

Styrene

Styrene, the base material for polystyrene from which EPS is made, has been discussed and studied in detail, including its health effects.

Polystyrene is an inert stable compound, no styrene is released during the foaming and moulding processes of manufacture or in the end use. Small amounts of Styrene, significantly below the safe limit values, can be released when cutting with heated wires in the factory.

EPS Disposal

Recycling

During manufacture all off-cuts and scrap is granulated and recycled directly into the production of new EPS material. Clean waste used EPS can also be granulated and added to new material, saving valuable resources.

Energy Recovery

EPS has an excellent calorific value for energy recovery. The process of producing energy from waste materials such as EPS helps to save fossil fuels. Incinerating 1kg of EPS saves 1.3 litres of heating fuel.

Landfilling

This is the least desirable end-of-life use for EPS and is only carried out when the possibility of recycling or energy recover are excluded. Where this is the only option, EPS can be placed in landfill without risk. EPS is inert, biologically harmless and non-toxic. (see also Safety Data Sheets).

Build a Better Environment with Sundolitt EPS